- Home

- Products

- Conveying Equipment

- Buried Scraper Conveyor

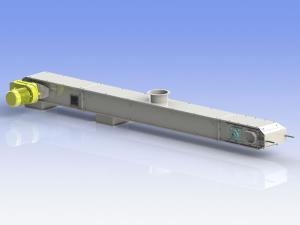

Buried Scraper Conveyor

The buried scraper conveyor gets its name because the scraper chain is buried in and moves along with the target materials when working. It is designed to transport powders, particles or small bulk materials in the horizontal, vertical or inclined direction, and it has been widely accepted in food processing, chemical engineering and many other fields due to its big conveying capacity and long conveying distance.

| Model | Chute Width (mm) | Chains Distance (mm) | Scraper Plate Form | Conveying Capacity (t/h) |

| |

240 | 55 | T | 16-20 |

| |

315 | 70 | T | 20-25 |

| |

320 | 100 | T | 60 |

| |

400 | 160 | T | 100 |

1. Safe Operation

For safety considerations, all the moving parts are equipped with protective covers. So, the operators are perfectly protected from any potential danger.

2. Sturdy Construction and Low Maintenance Requirement

This buried scraper conveyor is scientifically designed, and we paid special attention to its sturdy construction. The core part of our machine is the drop-forged and hardened chain which exhibits pretty high tensile strength and good wear-resistance, while the sprockets and chain links are connected by bolts. This design simplifies and quickens the replacement of components.

On the other hand, fewer expendable parts are used, so the maintenance cost is also cut down greatly.

3. Modular Design and High Versatility

The machine surface could be covered with single or multi layers of powder coating, and galvanization treatment is also available. So, our buried scraper conveyor suits for delivering various kinds of materials indoors and outdoors, and different kinds of wear-resistant metal or plastics could be adopted to further improve its application fields.

Related Names

Grain Conveying Machine | Bulk Material Conveyor | Automated Conveyor